Sandblasting machines

Your sandblasting machine directly from the manufacturer!

SAPI - As a leading manufacturer of professional blasting systems of all kinds and with over 50 years of experience in the field of surface treatment, we will find the right blasting machine for you and your application.

SAPI blasting machines have been used successfully around the world for many decades, are manufactured in accordance with all applicable requirements, standards and regulations and are suitable for professional use. Whether for large industrial companies, professional blasting operations or for the hobby sector, we make no distinction in the design.

You will only find the BEST QUALITY, which has proven itself thousands of times worldwide and is designed for maximum efficiency.

Your extremely robust and therefore extremely durable SAPI sandblasting unit will continue to "blast" reliably with you for many years to come

We will be happy to provide you with comprehensive advice to find the right sandblasting machine for you, including the necessary accessories such as protective equipment or abrasives. Our trained staff will be happy to assist you.

You are also welcome to visit us in our production facility and showroom at our location in DE-86753 Möttingen to see the quality and workmanship for yourself. Through our technical field service, we also offer instructions including training of the operating personnel.

As a manufacturer of blasting machines, we can of course also meet your individual special requirements in terms of design, equipment or coloring.

Your advantages:

- universal sandblasting unit direct from the manufacturer

- pressure regulated from 0.1-12 bar

- Extremely robust design for professional use

- suitable for all commercially available types of abrasive

- individual special designs possible.

- all pressure vessels are TÜV-tested

- Comprehensive advice and technical support

- Spare parts and accessories always in stock.

Below you will find a selection of mobile sandblasting units, pressure blasting units, low-pressure gentle blasting units, injector blasting units, dust-free blasting units and blasting units with abrasive cleaning.

Sandblasting unit application:

SAPI sandblasting machines are suitable for a wide range of applications in the field of surface treatment.

Are you looking for a pressure blasting unit or free blasting unit for classic applications such as paint and rust removal from components such as commercial vehicles, steel parts, vehicle parts, machine parts or industrial plants?

Would you like to gently sandblast wooden and natural stone buildings or remove graffiti from surfaces? By selecting the right blasting unit in conjunction with the appropriate blasting nozzle technology and blasting medium, there are almost no limits to surface treatment.

With the right configuration of your blasting unit, you can also cover all areas of blasting technology with just one blasting unit.

If you want to work dust-free / low-dust, use a suction back blasting unit. We manufacture the dust-free sandblasting unit both in a handy version for smaller applications and as a mobile, dust-free pressure back suction blasting unit with maximum performance.

Looking for spare parts?

Click here and browse through our spare parts catalog for sandblasting machines!

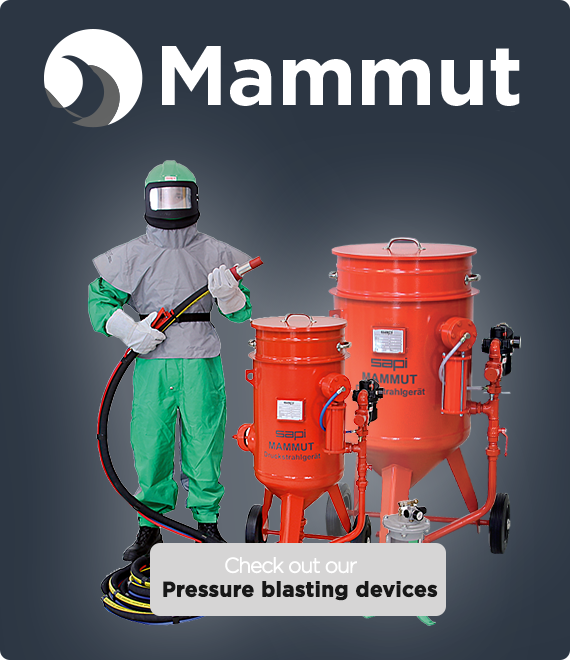

MAMMUT sandblasting machines - performance and reliability for professional requirements!

Sandblasting machines from SAPI meet all current safety regulations. The high quality standard of the equipment, our service and trained personnel ensure optimum support for our customers.

Our MAMMUT sandblasting machines are available with two different shut-off systems:

- Inlet and outlet valve

- Safety shut-off with a squeegee

For effective and economical sandblasting, we recommend sandblasting machines with the proven SAPI safety shut-off system!

ADVANTAGES OF THE SAPI PRESSURE JECTOR with safety cut-out:

- Fastest switch-off and switch-on times, complying with the regulations of the employers' liability insurance associations (VBG 48)

- The pressure setting can be precisely adjusted from 0.1 - 12.0 bar before the actual blasting process.

- Lower abrasive consumption, as the pressure tank remains permanently pressurized and therefore no unnecessary overrun of abrasive occurs.

- When restarting, the full blasting pressure is immediately available at the nozzle and does not have to be built up slowly, resulting in significantly lower abrasive consumption and considerably less wear on the blasting hose.

- No formation of moisture (condensate) in the tank, as the tank remains constantly pressurized and is not vented and aerated at every start and stop. This method also offers other advantages as follows:

- Optimum abrasive metering with hardened fine metering valve

- Lower compressed air requirement, resulting in a significant reduction in fuel consumption (diesel)

- One-man operation, as the blasting pressure is constantly displayed by the container pressure and can be easily changed on the pressure gauge without having to start the machine first.

- No fault-prone device components such as control valves, diaphragms and seals, making it maintenance-friendly and reliable. Only the blasting hose in the safety cut-out needs to be checked and replaced if necessary and seals, making it easy to maintain and safe to operate. Only the blasting hose in the safety cut-out needs to be checked and replaced if necessary

MAMMUT pressure blasting units are suitable for all commercially available blasting media for dry, damp or wet blasting. All SAPI blasting pots are TÜV tested up to 12 bar. TÜV boiler papers are supplied on request. The scope of delivery of the pressure blasting pot includes: the blasting mixing chamber, as well as the air dosing device and the chassis. Equipped with crane eyes, manhole, fixed piping, rubber cone and cone seal. The sandblasting units are primed and impact-resistant painted. Detailed operating instructions are included with each unit.