Injector sandblasting cabins

SAPI injector sandblasting cabins are suitable for professional applications and, depending on the extraction system selected for continuous operation. In most cases, depending on the application, glass blasting beads, corundum and plastic blasting media are used.

Metallic blasting media such as chilled cast iron, cast steel or stainless steel blasting media on the other hand, are compatible only with pressure blasting cabins and are not suitable for dust-free sandblasting cabins. Due to the high bulk density of these types, the blasting media cannot be sucked by the system.

All blasting cabins from our production are equipped with a pressure control unit by default. This allows you to set the desired blasting pressure gradually. In the case of injector blasting cabins, the blasting medium is sucked in from the blasting medium collecting funnel by means of negative pressure in the blasting head and exits at the blasting nozzle. Due to the fact, the systems are also called suction jet systems.

Injector blasting systems are also easy to recognize by the fact that two hoses are led to the blasting head. Due to a certain ratio between the built-in air and jet nozzles, a vacuum is created in the mixing chamber, which sucks in the blasting agent and accelerates it to the surface of the treated piece. One advantage of injector blasting cabins is the lower air consumption compared to pressure blasting systems. The air consumption of suction blasting cabins is between 300 and 1,000 l / min. On the other hand, pressure sandblasting cabins should have at least a compressor output of around 1,500 l / min. Air consumption depends primarily on the individually used and installed nozzle sizes.

- Widder 70 | Injector sandblasting cabin | integrated cartridge filter system€6,591.41 €5,539.00plus 19% VATShipping not included

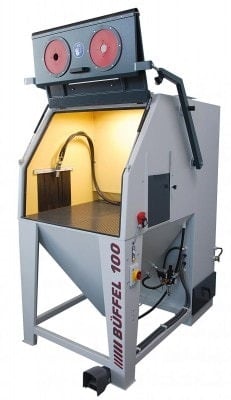

- Büffel 100 | Injector sandblasting cabin | with integrated filter system€8,199.10 €6,890.00plus 19% VATShipping not included

- Büffel 140 | High-performance injector sandblasting cabin€6,533.10 €5,490.00plus 19% VATShipping not included

- Büffel 140 | Injector sandblasting cabin | with integrated filter system€9,853.20 €8,280.00plus 19% VATShipping not included

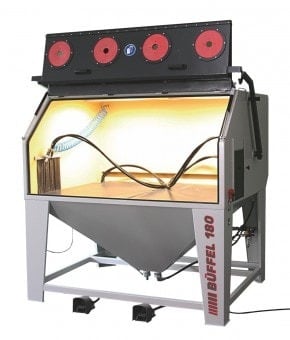

- Büffel 180 | High-performance injector sandblasting cabin€8,984.50 €7,550.00plus 19% VATShipping not included

- Büffel 180 | Injector sandblasting cabin | with integrated filter system€14,101.50 €11,850.00plus 19% VATShipping not included

- T-Rex 100 | High-performance pressure & injector sandblasting cabin | Double power€12,245.10 €10,290.00plus 19% VATShipping not included

- T-REX 140 | High-performance pressure / injector sandblasting cabin | Double power€19,016.20 €15,980.00plus 19% VATShipping not included