Büffel 180 | High-performance injector sandblasting cabin

"Büffel 180" high-performance injector sandblasting cabin. Loading takes place via a front flap which enables loading with a forklift or crane. Sandblasting room dimensions (W x D x H): 1,750 x 1,400 x 900 mm. Loadability of the work grate max. 300 kg.

Description

SAPI high-performance injector sandblasting cabin type "Buffalo 180"

The suction sandblasting cabin of the type "Büffel 180" is a compact injector sandblasting cabin. The sandblasting cabin takes up little space and is easy to move using a lift truck or forklift.

The sandblasting cabin is equipped with 2 injector sandblasting heads and 2 footswitches, this enables 2 people to work on the sandblasting cabin at the same time. The jet pressure can be regulated separately for each jet head.

Our high-performance injector sandblasting head (fresh sandblasting head) achieves a high negative pressure and thereby achieves a high sandblasting power, which enables fast, economical work with the negative pressure sandblasting cabin. The sandblasting nozzle is made of boron carbide and has an extremely long service life, even when using corundum sandblasting media.

To illuminate the sandblasting room, a modern, energy-saving LED light is attached to the cabin roof, protected from dust. This ensures optimal illumination of the sandblasting room of the sandblasting cabin and enables fast, fatigue-free and economical work.

Our sandblasting cabins are made of strong sheet steel, which enables the work grate to have a high load-bearing capacity.

All SAPI sandblasting cabins meet all current safety standards and are equipped with a door safety switch, which stops the sandblasting process immediately if the cabin is opened during the sandblasting process.

An additional extraction system is required for optimal operation of the sandblasting cabin. There are two different versions to choose from, depending on the purpose and duration of use.

The extraction system ensures optimal visibility in the sandblasting room, a dust-free work environment and is responsible for cleaning the sandblasting media used.

By using the right filter system, optimal abrasive cleaning is achieved in order to guarantee the maximum service life of the abrasive used.

Corundum, glass beads, plastic granules, vegetable granules, etc. can be used as sandblasting media.

Technical specifications:

| Overall dimensions | |

| Total height: | 1.800 mm |

| Total width: | 1.800 mm |

| Total depth: | 1.600 mm |

| Dimensions sandblasting room | |

| Width: | 1.750 mm |

| Depth: | 1.400 mm |

| Height: | 900 mm |

| Technical characteristics | |

| Air consumption: | 600 - 2.000 l/min. |

Nozzle: | 2 Stück Ø 8 mm Boron carbide sandblasting nozzle (optionally other diameters) |

| Air nozzle: | Ø 3,5 mm |

| Air pressure: | 2 bis 12 bar |

| Load capacity of the grating: | ca. 300 kg |

| Electrical connection: | 230 V / 50 Hz |

| Power consumption: | ca. 80 Watt |

| Color: | Basic body RAL 7035 light grey Add-on parts RAL 7016 anthracite grey |

| Weight: | ca. 450 kg |

| Technical changes reserved! | |

Scope of delivery:

- "Buffalo 180" sandblasting cabin

- Fresh blasting head with boron carbide sandblasting nozzle

- Pressure regulator to adjust the sandblasting pressure with integrated water separator

- LED lighting, attached to the cabin roof to protect it from dust

- Door security switch

- On/off footswitch

- Rubber rosettes

- 1 pair of rubber gloves (emitter gloves)

Advantages of the SAPI high-performance injector sandblasting cabin:

- Universally applicable blasting cabin for economical, highly efficient execution of all sandblasting work

- Suitable for all common types of abrasive

- Extremely robust front flap system developed by practitioners for maximum durability and dust-tightness

- Compact, portable design with an integrated cartridge filter system

- Extremely bright, glare-free illumination of the blasting cabin interior with LED light

- Extremely economical price/performance ratio

- Movable with a pallet truck, wheelchair-accessible construction

Application areas:

- Rust removal

- Paint stripping

- Descaling

- Deburring

- Hardening

- Lapping

- Glass bead rays

- Aluminium and stainless steel processing

- Roughening surfaces

- Smoothing surfaces

Suitable abrasives:

- Corundum

- White corundum

- Ceramic beads

- Glass beads

- Broken glass

- Silicon carbide

- Garnet sand

- Plastic abrasives

- mineral reusable abrasives

Injector sandblasting cabins are not suitable for the use of metallic sandblasting media. A pressure blasting cabin is required for this.

Recommended accessories

Here you will find recommended accessories for the high-performance injector sandblasting cabin "Büffel 180". This accessory makes it easier for you to work with the blasting cabin and increases its efficiency.

The following accessories are available:

Rubber lining for Büffel 180: |  |

Air blow gun: |  |

Lateral insertion and push-through openings |  |

Special accessories

Here you will find special accessories for the high-performance injector sandblasting cabin "Büffel 180". This can increase productivity and make work easier.

The following special accessories are available:

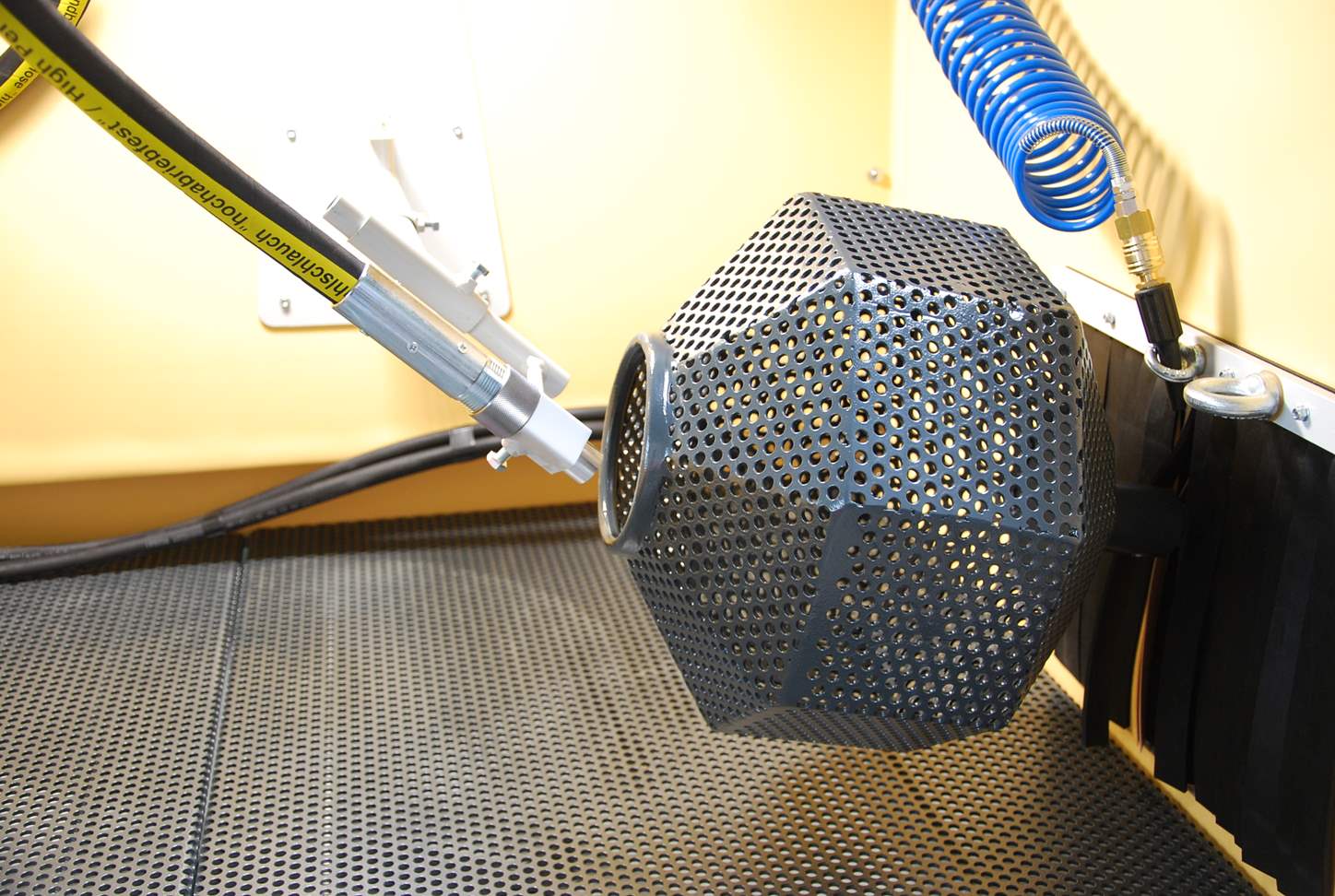

| Swivel arm with sandblasting head holder: The sandblasting nozzle can be fixed in the sandblasting head holder. Thus, the worker has both hands free to hold and rotate the workpieces. The swivel arm can be adjusted and fixed in angle and inclination. 3944.021 |  |

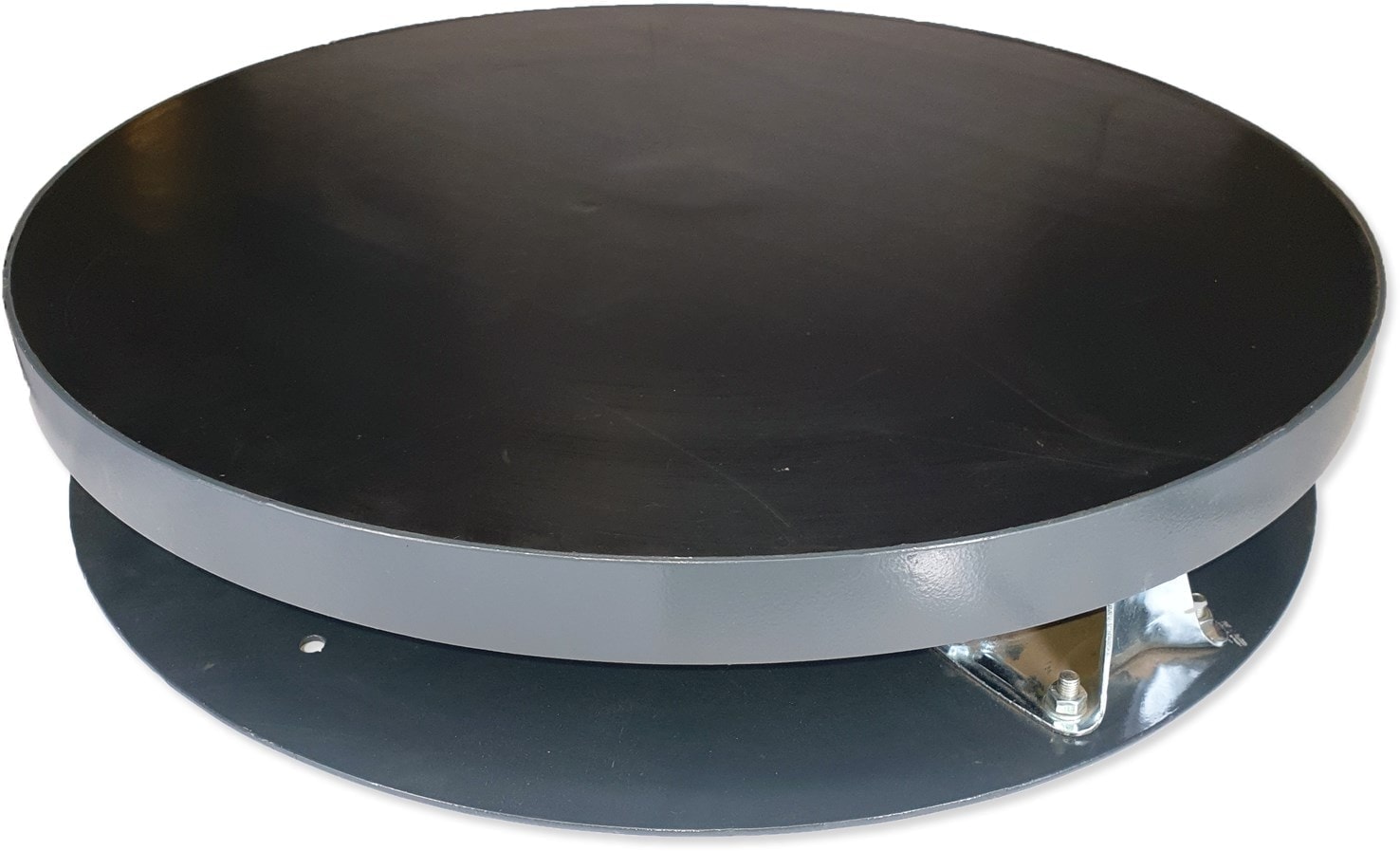

| Turntable ø 500 mm, manually operated: Enables the easier processing of heavy, unwieldy parts. The turntable is mobile and can be removed from the blasting room when it is not needed. Max. Load 40 kg. 9841.250 |  |

| Turntable ø 600 mm, manually operated: Enables the easier processing of heavy, unwieldy parts. The turntable is mobile and can be removed from the sandblasting room when it is not needed. Max. Load 200 kg. 9841.260 |  |

| Rotary plate ø 600 mm integrated into the work grate: The turntable is permanently integrated in the work grate and is operated manually. Even if the turntable is not required, a flat work surface is available. Max. Load capacity of 200 kg. 9841.285 |  |

| Rubber gloves permanently installed: The rubber gloves are connected directly to the cabin by means of a flange ring. 3941.135 |  |

There is also the option of equipping the sandblasting cabin with an automatic rotating basket or an automatic rotating plate. Extendable turntables are also available, these can either be extended halfway or completely extended using an additional loading trolley. We would be happy to advise you on this, speak to us.

| Automatic turntable: With this function, workpieces can be sandblasted automatically. The desired blasting duration and the desired speed of the turntable can be set on the control cabinet. After the set time has elapsed, the sandblasting process stops automatically. 9841.270 |

on request |

| Automatic rotating basket: With this function, loose parts can be sandblasted automatically. The desired sandblasting duration and the desired speed of the rotating basket can be set on the switch cabinet. After the set time has elapsed, the sandblasting process stops automatically. 9841.280 |

on request |

| The turntable can be extended halfway: The turntable can be pulled out about halfway. This enables easier loading using a crane or forklift. |

|

| The turntable can be moved out with a trolley: The turntable can be moved completely out of the cabin onto a trolley. The trolley can be moved to any point using castors. This enables the turntable to be equipped easily using a crane or forklift. |

|

Our delivery program also includes fully automatic special sandblasting cabins, which respond precisely to the needs of our customers. We would be happy to advise you, speak to us.

Extraction systems

For the optimal, economical operation of the "Büffel 180" sandblasting cabin, an extraction system is required, which ensures a negative pressure in the sandblasting room.

The filter system cleans the used sandblasting media and at the same time ensures a good view in the sandblasting room and a dust-free work environment.

Depending on the purpose and duration of use, different extraction systems are available:

Pocket filter suction system "TFA I" |  |

Cartridge filter "PC 1" |  |

We would be happy to advise you on the selection of the right extraction system, talk to us!

More Information

| SKU | 9413.180 |

|---|---|

| Delivery time | approx. 2 - 3 weeks |

| Shipping | Shipping not included |

| VAT | plus 19% VAT |

| Integrated filter | No |

| Door opening | Front flap |

| Max. Load capacity | 300 kg |

| Cabin Type | Injector |

T-REX 140 | High-performance pressure / injector sandblasting cabin | Double power€19,016.20 €15,980.00

T-REX 140 | High-performance pressure / injector sandblasting cabin | Double power€19,016.20 €15,980.00