Mammut 200 Liter | Pressure sandblasting machine with safety quick-stop device

Mobile 200 l pressure sandblasting device with inlet/outlet valve shut-off system (boiler ventilation shut-off), pressure-regulated from 0.1 - 12 bar, 1 "water separator permanently attached. Suitable for all common sandblasting media. TÜV-tested with CE declaration of conformity.

Our SAPI pressure blasting unit type "Mammut" with 200 litre tank capacity is suitable for all common blasting media. The blasting pressure can be adjusted continuously from 0.1 - 12 bar via the permanently installed pressure regulator. A water separator is also permanently attached to the blasting unit; this separates moisture from the compressed air and prevents the abrasive from clumping due to too much moisture.

For safe operation of the sandblasting unit, our safety shut-off is included. This starts and stops the blasting process by operating the hand lever, which is mounted on the blasting hose.

The scope of delivery includes:

- SAPI pressure blasting unit "Mammut 200 L".

- Pressure regulator 1 1/4", fixed

- Water separator 1 1/4", permanently attached

- SAPI safety cut-out

Technical data pressure blasting unit:

- precisely adjustable from 0.1 - 12 bar

- TÜV-tested with certificate

- Fixed piping 1 1/4" inside and outside

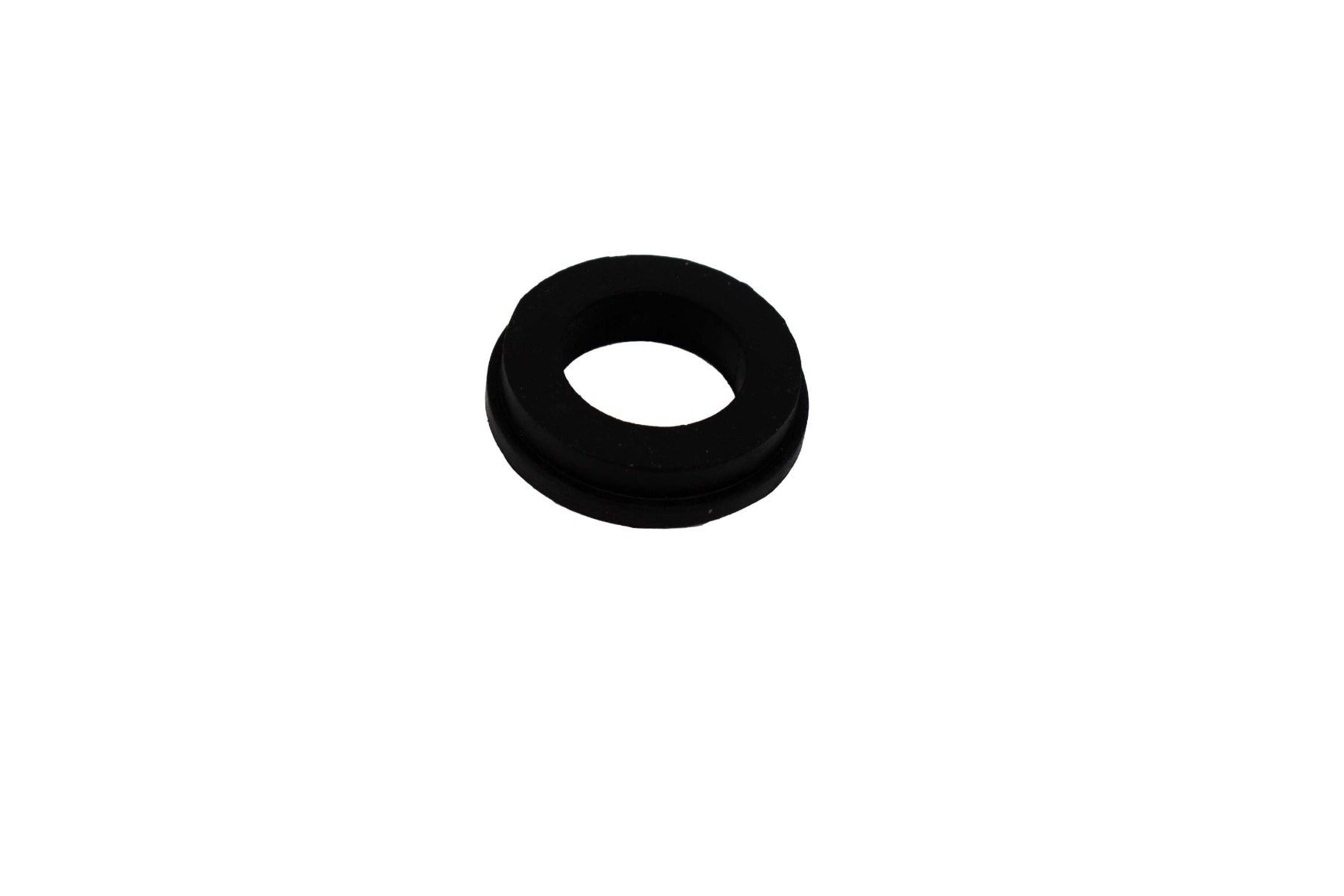

- Rubber-coated metal cone with rubber seal

- Generously sized hand hole

- Chassis with rubber wheels

- Blasting agent dosing valve (suitable for all common blasting agents)

- Capacity 200 l

- Total height 1,420 mm

- Boiler diameter 600 mm

- Total diameter 1,000 mm

- Weight approx. 140 kg

fastest switch-off and switch-on times, while complying with the regulations of the employers' liability insurance associations. (VBG 48)

fastest switch-off and switch-on times, while complying with the regulations of the employers' liability insurance associations. (VBG 48)- The pressure setting can be precisely adjusted before the actual blasting process from0.1 - 12.0 bar infinitely variable.

less abrasive consumption, as the pressure vessel remains permanently under pressure and thus there is no unnecessary run-on of abrasive. - When restarting, the full blasting pressure is immediately available at the nozzle and does not have to be built up slowly first. This results in significantly lower abrasive consumption and significantly less wear on the blasting hose.

- No formation of moisture (condensate) in the tank, as the boiler remains constantly pressurised and is not vented at every start and stop. This method also provides other advantages, such as the following:

- Optimum abrasive dosing with hardened fine dosing valve

- Lower compressed air requirement, resulting in a significant reduction in fuel consumption (diesel)

- one-man operation, as the blasting pressure is constantly indicated by the tank pressure and can be easily changed on the pressure gauge without having to start the machine first

- No failure-prone unit components such as control valves, diaphragms and seals, thus easy to maintain and reliable in operation. Only the blasting hose in the safety shut-off has to be checked and replaced if necessary.

Further accessories for pressure sandblasting devices, which make work easier:

Sandblasting media screens and lids for pressure sandblasting devices:

| Sandblasting media sieve for pressure sandblasting device When using bagged goods, the sandblasting media screen prevents pieces of paper from getting into the pressure vessel. In addition, if the abrasive is used several times, foreign matter is screened off. Article no. 3933.540 |  |

| Lid for pressure sandblasting device The lid protects the pressure sandblasting vessel from dirt and moisture. Article no. 3933.030 |  |

Sandblasting hose extensions fully assembled:

| 10 m sandblasting hose extension 19x7 mm cpl. assembled with 2 nylon hose couplings and control line. Article no. 9856.218 |  |

| 10 m sandblasting hose extension 25x7mm cpl. assembled with 2 nylon hose couplings and control line. Article no. 9851.610 |  |

| 10 m sandblasting hose extension 32x8 mm cpl. assembled with 2 nylon hose couplings and control line. Article no. 9851.710 |  |

Personal protective equipment (PPE) as a complete set for optimum protection of the worker during sandblasting work:

| Sandblasting protection package RED 2 consisting of: Blasting helmet "RED 2" with nylon jacket Sandblasting suit nylon/cotton 1 pair of blasting gloves leather Breathing air filter/activated carbon filter "SAF Connecting hose for breathing air filter 10 m breathing air hose 1 pack inner discs for "RED 2 1 pack wear plates for "RED 2 1 pack tear-off foils for "RED 2 Article no. 9891.160 Blaster protection package |    |

| Sandblasting protection package RED 1 consisting of: Blasting helmet "RED 1" with nylon jacket Sandblasting suit nylon/cotton 1 pair of blasting gloves leather Breathing air filter/activated carbon filter "SAF Connecting hose for breathing air filter 10 m breathing air hose 1 pack inner discs for "RED 1 1 pack of wear discs for "RED 1 Article no. 9891.150 Blast protection package |    |

| SKU | 9522.200_SAB_Q |

|---|---|

| Delivery time | approx. 1 week |

| Shipping | Shipping not included |

| VAT | plus 19% VAT |

| Sale_label | No |

| Volumen | 200 L |

| Size Blasting Pot | 200 Liter |

| Quick Stop | Yes |

- This Item: €4,782.61 €4,019.00

- NOVA 3 sandblasting protection packageSpecial Price €1,130.50 €950.00 Regular Price €1,287.34 €1,081.80Show details